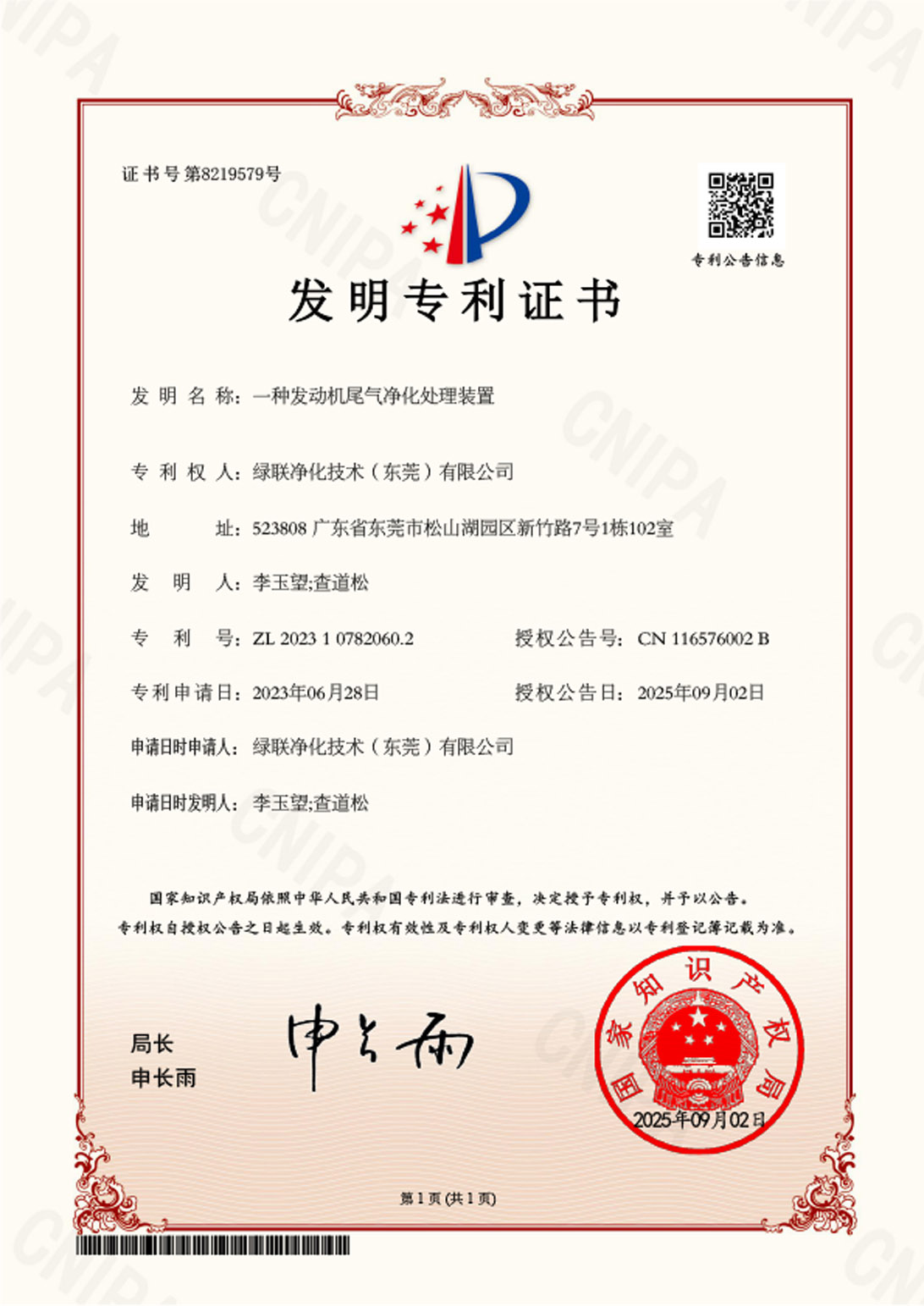

Warm CongratulationsLeelool Purification Successfully Obtains Authorization for Its Invention Patent

An Engine Exhaust Purification DevicePatent Number: ZL 2023 1 0782060.2

Patent Brief Introduction

Product Introduction

This device is tailor-developed exclusively for the dedicated test bench scenario of diesel engines used in a large domestic diesel generator set we supply. It focuses on addressing the pollutant treatment needs during the testing process: it not only achieves efficient, reliable, and precise treatment of over-sprayed diesel, black smoke, and nitrogen oxides, but also ensures the test bench operates continuously and stably without any interference throughout the entire process. Fundamentally, it avoids test interruptions or operating condition fluctuations caused by system intervention, guarantees a smooth entire test process and stable equipment operating conditions, and fully adapts to the long-term, high-frequency test operation requirements of the test bench.

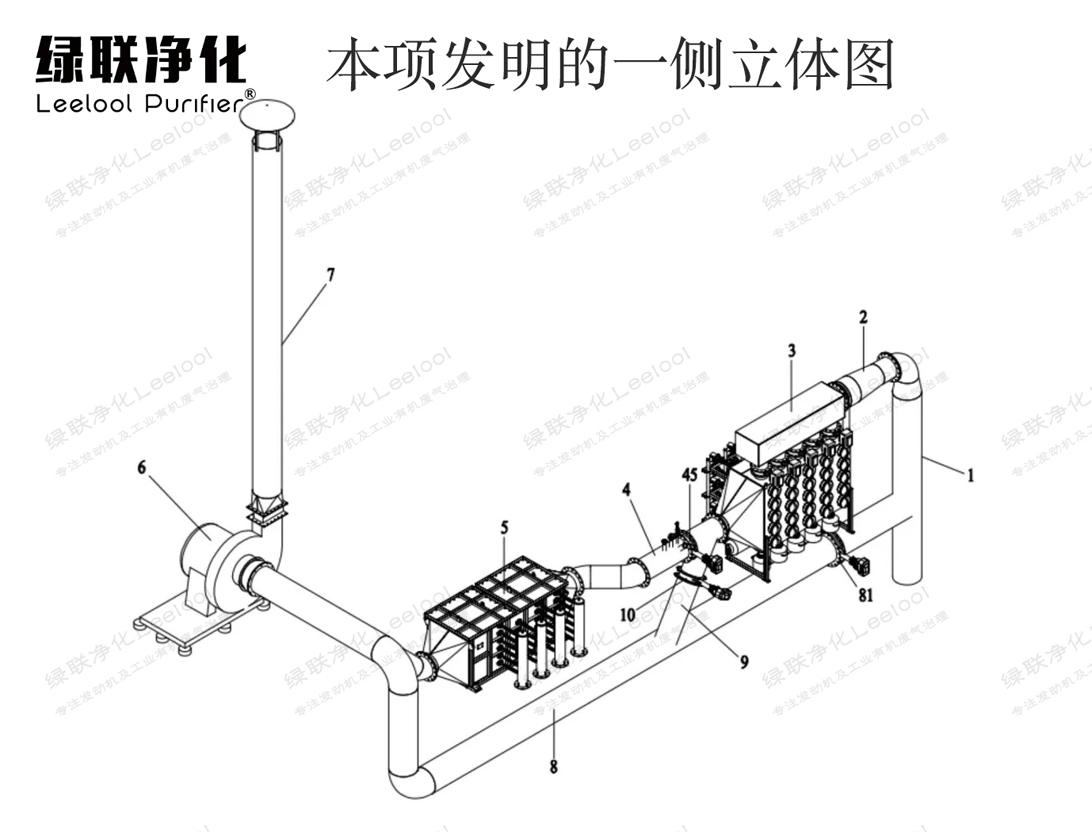

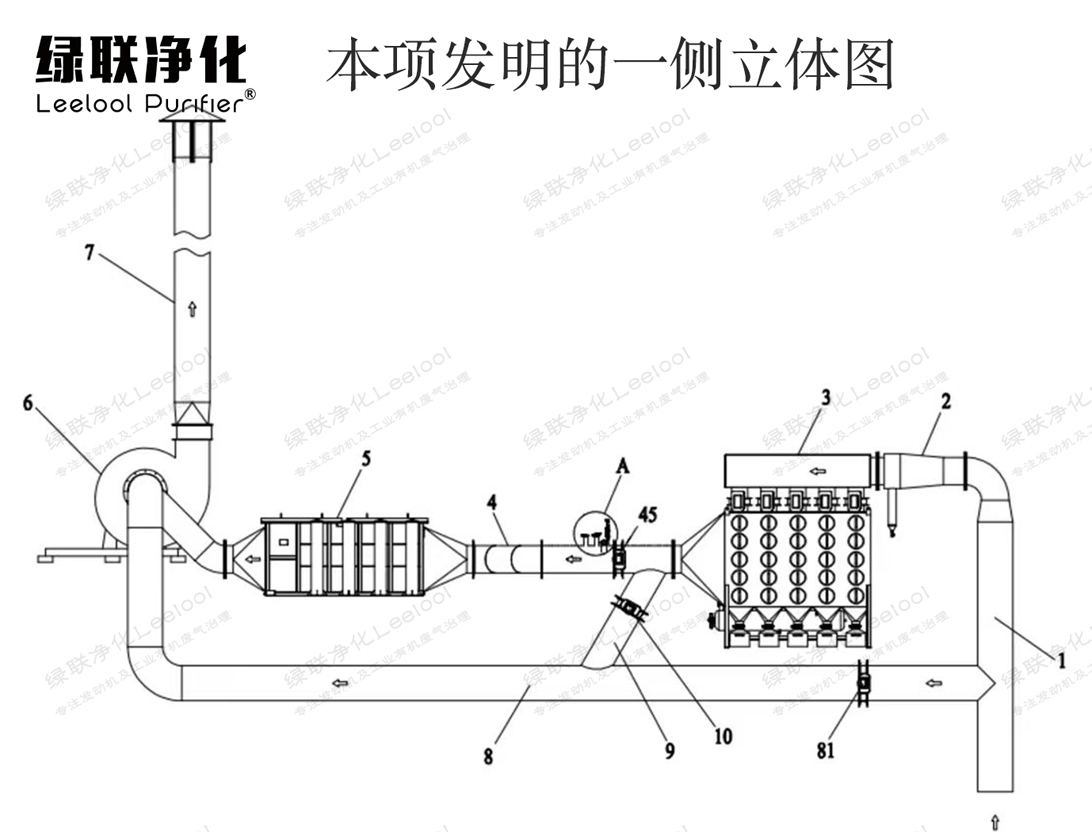

An Engine Exhaust Purification Device. The device consists of a smoke inlet pipe, an oil-gas separator, a back-blowing purification device, a mixing pipe, an ash blowing device, an induced draft fan, an exhaust pipe, and a bypass pipe. The smoke inlet pipe is in communication with the oil-gas separator, and the back-blowing purification device is also in communication with the oil-gas separator. One end of the mixing pipe is in communication with the back-blowing purification device, while the other end is connected to the ash blowing device. The outlet end of the ash blowing device is in communication with the induced draft fan, and the exhaust pipe is arranged at the outlet end of the induced draft fan. One end of the bypass pipe is in communication with the smoke inlet pipe, and the other end is in communication with the induced draft fan.

Working Principle

The working principle of this invention mainly consists of two key links: denitrification treatment and black smoke treatment.

In the denitrification treatment link, the technical route of Selective Catalytic Reduction (SCR) is adopted. The exhaust gas enters the ash blowing device through the mixing pipe, where the nitrogen oxides (NOₓ) in the exhaust gas are reduced to nitrogen (N₂) and water vapor (H₂O), ensuring that the emission of nitrogen oxides meets the standards.In the black smoke treatment link, this project is exclusively equipped with a 4th-generation back-blowing Diesel Particulate Filter (DPF) maintenance-free purification system.Engine test benches need to conduct continuous operating condition tests for long periods, requiring extremely high operating condition stability and test cycle continuity. To ensure the test bench’s operational continuity and the accuracy of emission data, we have selected a 4th-generation back-blowing Diesel Particulate Filter (DPF) maintenance-free purification system. The advantages of this system are mainly reflected in the following three aspects:

1.The maintenance-free design of the system eliminates the need for frequent shutdowns to disassemble, replace, or clean the DPF, thus avoiding interruptions to the test process.

2.Back-blowing regeneration does not require additional heating or chemical reagents, so it will not interfere with the original airflow field and temperature field of the test bench. This prevents variables from being introduced during the regeneration process, ensuring the accuracy of particulate emission data.

3.The system is suitable for multi-load test scenarios of the test bench. Its high capture efficiency enables stable treatment of particulates under different operating conditions, and there is no pipeline disassembly/assembly error caused by maintenance operations—this improves the repeatability of test data and meets the core needs of the test bench for data reliability and operational continuity.

In terms of application scenarios, the fourth-generation reverse-blow particulate trap (DPF) maintenance-free purification system, which is exclusively configured for this project, can stably cover the exhaust gas purification needs of high-horsepower engine bench tests, diesel generator bench durability tests, and industrial-grade power generation units (including scenarios such as backup power supplies and base station power supply). It fully meets the requirements for efficient purification and stable operation under different test scenarios.

Product Advantages

1. Oil-Gas Separator

By incorporating an oil-gas separator, this invention performs oil-gas separation treatment on engine exhaust gas. It prevents oil components from clogging the DPF filter element, thereby extending the interval between reverse-blow cleaning operations. Additionally, it stops oil from escaping into the SCR system, avoiding oil contamination-induced poisoning of the catalyst and ensuring the NOₓ removal efficiency. The system is adaptable to high-load test conditions of engines, providing crucial support for the long-term stable operation of the device while reducing operation and maintenance costs.

2. Maintenance-Free Black Smoke Purification

This invention adopts a fourth-generation maintenance-free black smoke purifier, equipped with high-pressure pulse reverse-blow technology and differential pressure closed-loop control technology. When carbon deposition reaches the threshold value, it automatically triggers high-pressure ash cleaning at 0.8-1.2MPa, eliminating the need for manual disassembly and cleaning of the filter element. This completely avoids the problems of test interruption and DPF carrier damage caused by the need for shutdown maintenance in the third-generation products.The particulate collection efficiency of the maintenance-free black smoke purifier is ≥95%. It is suitable for scenarios such as high-horsepower engine test benches and generator sets, and can still operate stably under full-load conditions. It not only reduces labor and operation and maintenance costs but also ensures that the purification efficiency does not decrease, and can support continuous test requirements for more than 72 hours.

3. Bypass Control for Pressure Regulation and Flow Discharge

When the backpressure sensor of the mixing pipe detects that the inlet pressure exceeds the limit, the control valve will immediately connect the bypass pipe and the induced draft fan, guiding part of the exhaust gas to flow through the bypass pipe to the induced draft fan for discharge. This maintains the smooth exhaust of the soot-blowing device, prevents the engine from stalling due to increased backpressure, and ensures the safety of the engine's operation. The entire pressure control and flow discharge process is characterized by timely response, high efficiency and reliability.

An Honor, A Responsibility

The successful granting of this invention patent is not only an honor and affirmation for us, but also a responsibility on our journey forward. It belongs to every partner who has strived for Leelool Purification, and to every friend who has placed their trust in us. We will turn this honor into motivation, unswervingly invest in research and development, enable more innovative technologies to take root, and contribute tangible value to the goals of sustainable development. We have always believed that win-win cooperation is the cornerstone of development, and we eagerly look forward to working with more partners to create a beautiful future with blue skies and white clouds. On the road ahead, let us continue to stand side by side, repay this trust with more technological achievements, and add more green vitality to our Mother Earth!